Efficient air compressor systems are the backbone of smooth industrial operations, influencing energy usage and long-term equipment reliability. Whether you manage a facility in a large warehouse or oversee small-scale manufacturing, prioritizing proven maintenance practices leads to tangible gains in performance and cost efficiency. If you operate in regions like North Florida, particularly when maintaining an air compressor line Jacksonville, FL facilities rely on ensuring system reliability, which is especially vital for operational continuity and minimizing unplanned downtime.

Regular maintenance of compressed air systems directly translates into reduced waste, consistent output, and fewer costly breakdowns. Companies across diverse sectors underscore that investing in preventive and predictive approaches not only preserves compressor integrity but also delivers measurable energy savings. Early identification of minor issues can prevent major repairs, ensuring your compressed air system delivers optimized performance for years to come.

Many industries experience fluctuating demand and challenging environmental factors, which can take their toll on air quality and system efficiency. Maintenance isn’t just about repairs; it’s about creating processes that foster peak compressor performance and support sustainable facility growth. These comprehensive strategies can help you build more resilient air systems, reduce emissions, and improve the overall efficiency of your entire production line.

Learning and applying current best practices allows maintenance teams to navigate the unique challenges of their specific setting, whether dealing with humid climates, dusty environments, or high runtime requirements. The following guide details the most effective techniques and tips you can implement today to keep your air compressor systems functioning at optimal levels and ensure compliance with evolving industrial standards and guidelines.

Table of Contents

Regular Inspections

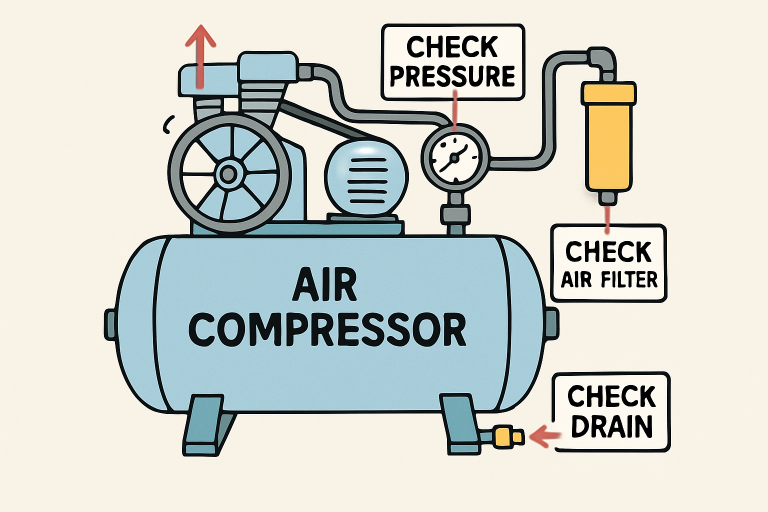

To keep air compressor systems running at peak efficiency, consistent and comprehensive inspections are essential. Begin with visual and auditory checks, listen for unusual noises that could signal worn components, and look for loose bolts, cracked hoses, or signs of oil leaks. Inspect electrical connections, control panels, and safety shutdowns to catch minor faults before they escalate. Simple visual inspections, performed weekly or monthly, serve as the first line of defense against more costly failures.

Incorporate manufacturer maintenance schedules, but supplement them with your facility’s specific runtime data and unique usage patterns. For example, an air compressor in a dusty facility may need filter replacements more often than one in a cleaner environment. Leveraging tools and checklists approved by industry groups, such as the Compressed Air & Gas Institute, can help standardize inspections and ensure nothing critical is overlooked.

Monitoring Air Intake Quality

The environment from which a compressor draws air plays a pivotal role in system performance. Ideally, compressors operate best when drawing in cool, clean, and dry air. Inspect and replace intake filters at intervals appropriate to your operating environment, and regularly monitor for dust and debris buildup. Poor air intake not only reduces compressor efficiency but also increases wear on internal components, shortening the system’s lifespan.

Positioning the air intake in a shaded, well-ventilated area, away from vehicle exhaust, airborne oils, or compressor discharge vents, can significantly enhance performance. Unchecked contaminants such as humidity, vaporized chemicals, or dust particles can accumulate in your air network, harming both the compressor and downstream applications. According to the U.S. Department of Energy, routine monitoring and addressing air intake issues are among the simplest ways to promote energy savings and operational consistency.

Maintaining Optimal Operating Pressure

Operating compressors at unnecessarily high pressures is a leading cause of wasted energy. Facilities too often set pressure levels well above what is actually required for end-use equipment, mistakenly assuming it improves performance. In reality, every 2 psi increase in system pressure may raise energy usage by up to 1%, costing thousands in extra electricity annually. Keeping the system at the lowest acceptable setting and using precise regulators, rather than general over-pressurization, minimizes waste and wear.

Use digital pressure sensors and storage tanks to buffer against demand peaks and stabilize supply to production lines. Regularly review the requirements of all production-floor applications, adjust your pressure accordingly, and consult with an air system professional as new tools or pieces of equipment are added to avoid runaway pressure costs.

Detecting and Repairing Leaks

Air leaks plague many industrial sites, accounting for up to 30% of a compressor’s output loss if left unchecked. Regular pressure checks, combined with ultrasonic leak detectors, can quickly identify and quantify leaks, enabling prompt repairs. Maintenance staff should create a log and schedule for inspecting fittings, couplings, hoses, and valves and document any repairs to monitor trends over time.

Even minor leaks, such as a single 1/8-inch hole in a 100 psi system, can waste over $1,200 of electricity per year, according to ENERGY STAR. Investing in a robust leak detection program will quickly deliver a strong return on investment, not just through energy savings, but also in improving plant reliability and extending equipment life.

Implementing Heat Recovery Systems

One of the most overlooked aspects of compressor system efficiency is the recovery and repurposing of waste heat. Up to 90% of the electrical energy used by a compressor is converted into heat, which can be captured and reused for heating process water, space heating, or preheating boiler feedwater. Modern heat recovery units are compact and can often be retrofitted with minimal downtime.

By integrating a heat recovery system, facilities can both reduce energy bills and support wider environmental and sustainability goals. This not only boosts your facility’s operational efficiency but also helps meet regulatory requirements concerning energy use and emissions reduction. Energy and facilities managers should assess current system configurations and consult with providers to determine suitable heat recovery solutions.

Upgrading to Direct-Drive Compressors

As production scales, upgrading from belt-driven to direct-drive air compressors can deliver substantial efficiency gains. Belt-driven compressors are prone to slippage and stretching over time, leading to excess heat and requiring frequent adjustments to maintain optimal performance. In contrast, direct-drive compressors eliminate these inefficiencies by coupling the drive motor directly to the compressor, ensuring maximum power transfer at full load and lowering ongoing maintenance requirements.

While the upfront investment may be higher, long-term labor and energy savings make direct-drive systems an increasingly attractive option for expanding facilities. Consult with air system engineers to perform a cost-benefit analysis tailored to your operation’s unique needs before making major upgrades.

Conducting Predictive Maintenance

Predictive maintenance harnesses the power of digital monitoring, sensors, and analytics to interpret equipment behavior and flag anomalies before they evolve into failures. By using sensors to log vibration, temperature, oil quality, and other key data points, predictive models can alert teams to impending bearing or motor problems, ensuring repairs are scheduled proactively and reducing costly downtime.

Integrating this approach with existing CMMS systems and training technicians in the use of diagnostic tools shifts maintenance from reactive to preventive, reducing overall costs and improving safety. Artificial intelligence and machine learning platforms are increasingly valuable additions for companies intent on maximizing uptime and resource efficiency.

Conclusion

A well-maintained air compressor system underpins operational excellence in manufacturing and industrial settings. By conducting regular inspections, monitoring air intake quality, maintaining optimal pressure, addressing leaks, implementing heat recovery, upgrading to direct-drive technology, and deploying predictive maintenance, facilities can cut costs, boost performance, and extend system lifespan. With a growing focus on energy efficiency, these strategies offer a clear framework for building a robust compressed air network that delivers reliable, sustainable value over time.

- How to Buy a Home in Today’s Market - February 13, 2026

- Common Causes of Car Accidents and How to Avoid Them - February 13, 2026

- Innovative Strategies for Effective Event Staffing - February 12, 2026